Description

Structure

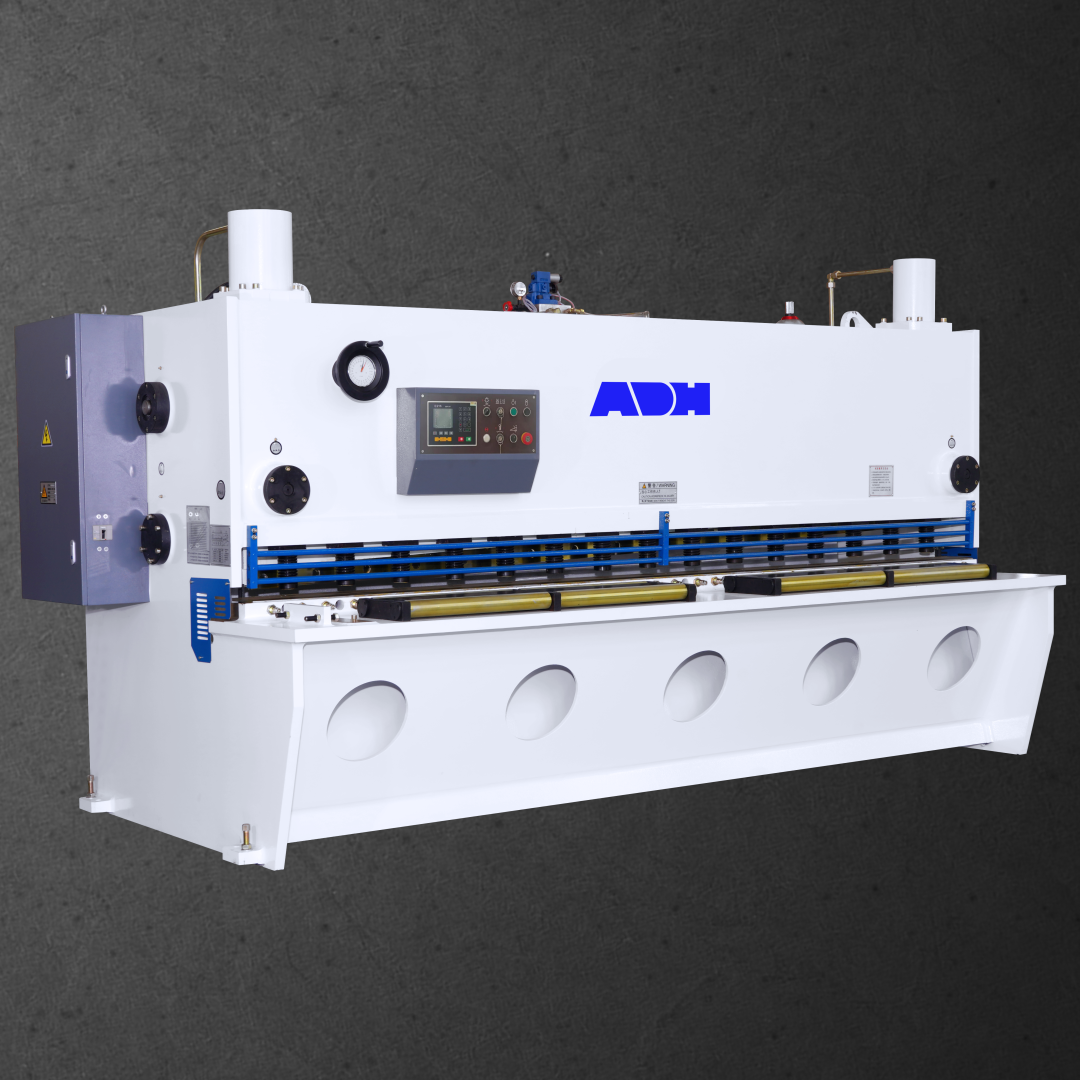

- The design of the shearing machine includes a box bed frame completely welded with the workbench.

- The frame can produce high stiffness to balance the torque load generated by shear force.

- Vertical linear movement relative to the lower blade to ensure that the shear sheet has less distortion and more accurate straightness.

- The main frames, after welding & milling, are heat treated, Annealed in an Annealing furnace to relieve the stresses caused by the above action. This gives better rigidity to the structure.

Control System

- Estun E21S digital display controller is provided for NC Shearing Machines.

- The back stop, blade angle and blade gap can be controlled and adjusted in the system.

- The controller is DAC360 CNC system of Delem brand in the Netherlands (now upgraded to DAC360T touch screen) for CNC Shearing Machine

Main Drive

- High performance main motor can be equipped with international brand such as Siemens or Chinese famous brand WN.

- Country specific Voltage customization can be done

Hydraulic Valve

- International brand Rexroth hydraulic valve block is adopted.

- With oil pressure overload protection, oil leakage and valve jamming are rare.

- Real time oil pressure monitoring to ensure smooth oil circuit and stable running of the equipment.

Feeding Port

- The design of feed port complies with international safety standards.

- The minimum feeding height is the sheet thickness, and the maximum is the sheet thickness plus 20-25mm. There are adjustable height screws to adjust the feeding height.

- The front fence and side guardrail ensure safe operation.

Cutting Line Illumination

- It is equipped with light alignment device, which is convenient for marking and shearing, and can stepless adjust the stroke of the blade holder.

Servo driven Back gauge

- Pneumatic rear support device and rear light curtain protection device are optional.

- The automatic rear support plays a supporting role in cutting the thin plate to ensure the cutting accuracy and surface finish of the plate.

- The rear light curtain protection protects personal safety during the operation of the machine and complies with international safety standards.

- The rear servo reduction motor has good quality and fast positioning speed of simulation operation.

Electrical Components

- High-quality electrical components are adopted, which are stable and durable with long service life.

Hydraulic Oil Cooling Device

- In high temperature environment, the machine can be used continuously for a longer time. This is an optional device

Pneumatic Rear Support

- It is convenient for customers to cut wide sheets, which can be closed with one key when not in use. This is an optional device

Rear Protection Device

- Photoelectric protection to protect personal safety, especially finger safety. This is an optional device

Lubrication Device

- It is more convenient and faster. There are two models: automatic and manual, which are convenient for customers to choose.

Ball Integrated Front Tables

- The ball type front support reduces the friction between the plate and the table, and ensures the smoothness of the plate surface.

- The feeding is more convenient and fast, and the cutting efficiency is improved.